Inflow™ Plus 235

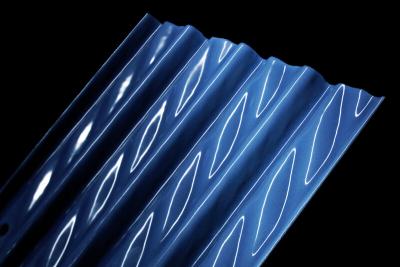

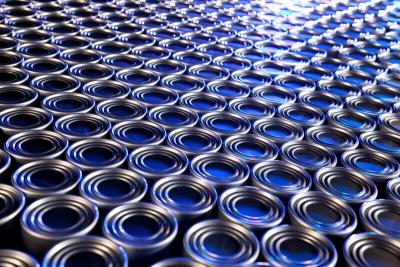

Inflow™ Plus 235 multi-certified, hot-finished High Frequency Induction welded pressure tube.

Inflow™ Plus 235 multi-certified, hot-finished HFW (High Frequency Welded) pressure tube for general purpose and industrial conveyance solutions such as HVAC, steam services, petrochemical, process plant and fire protection applications.

Click the logo above to download the BIM Object for this product.

EN-Construction-Product-Inflow Plus 235

EN-Construction-Product-Inflow™ Plus 235 | Product Overview

-

Inflow™ Plus 235 multi-certified, hot-finished High Frequency Induction welded pressure tube.

-

Inflow™ Plus 235 multi-certified, hot-finished HFW (High Frequency Welded) pressure tube for general purpose and industrial conveyance solutions such as HVAC, steam services, petrochemical, process plant and fire protection applications.

EN-Construction-Product-Inflow Plus 235 | Features and benefits

Features and benefits

<ul> <li>Primary standard EN 10217-2 Grade P235GH.</li> <li>Quality designation TC1 supplied as standard.</li> <li>Quality designation TC2 option for sizes ≥OD219.1mm.Multi-certified satisfying the mechanical properties of grades in other industry referenced standards, please refer to product brochure for full details.</li> <li>Suitable substitute for equivalent hot-finished seamless tube grades e.g. ASTM A106 Grade B, EN10216-2 Grade P25GH & DIN1629 St37.0N.</li> <li>Boiler tube option, delivering additional alignment to generally equivalent industrial standards, available upon request, at time of order.</li> <li>General engineering tube to EN 10219 Grade S235JRH/S275J2H (for sizes greater than, equal to OD219.1mm).</li> <li>Fully weldable.</li> <li>Fully killed steel produced to fine grain practice for enhanced ductility.</li> <li>Full PED compliance being suitable for equipment in PED categories I, II, III or IV, also aligned with AD2000 Merkblatt W4.</li> <li>Suitable for pressure applications and temperature range -20 to +400ºC (except EN 10219).</li> <li>Lower temperature option of -40 ºC available upon request, at time of order (except EN 10219).</li> <li>OD and ID weld beads fully removed.</li> <li>Backed up by technical experts who can offer advice on applications and product suitability.</li> <li>Fully technically supported with a range of available product brochures.</li> <li>Certified to BES 6001 Responsible Sourcing standard.</li> <li>Supplied with 3.1 inspection certification to EN10204.</li> </ul>

EN-Construction-Product-Inflow Plus 235 | Mechanical properties

| Inflow™ Plus 235 | ||

|---|---|---|

| Delivery condition | Cold | N/A |

| and size range | Hot | OD17.2 - 193.7mm |

| WLA (Weld Line Anneal) | OD219.1 - 508mm | |

| Main targeted application | General purpose pressure and | |

| industrial conveyance | ||

| Elevated temp | ||

| industrial pressure | ||

| Primary grade/min yield strength MPa | 245 | |

| Tensile strength MPa | 360-500 | |

| Elongation (longitudinal min) % | 25 | |

| Standard temperature range (°C) | -20 to 400 | |

| Low temp option (request at time of order) | -40 | |

| Suitable alternative to seamless | Yes | |

Please refer to the relevant technical literature for confirmation of the EN10219 properties.

EN-Construction-Product-Inflow Plus 235 | Dimensions and pressure ratings

EN-Construction-Product-Inflow Plus 235-downloads

Downloads

<p></p>

EN-Construction-Datasheet-Technical Support Document

Building and Industrial Services - Technical Support Document

EN-Construction-Contact-tubes

Call our tubes hotline

Tata Steel

Weldon Road

Corby

Northants

NN17 5UA