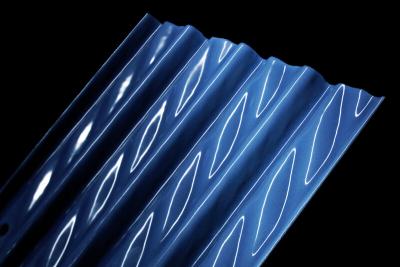

High strength, low weight

Manufactured from thin gauge pre-finished steel Advantica provides exceptional rigidity at a relatively low weight compared to other alternatives. The reduced weight vehicles in turn reduces fuel consumption and CO2 emissions, making the trailers more efficient to operate.

Superior thermal performance

Used for the construction of the internal and external sides of composite panels, Tata Steel pre-finished steel products offer increased thermal performance over alternative materials.

Strong and durable bond

Continuous product testing and working alongside leading trailer manufacturers has helped us develop a proven adhesion system that ensures excellent strength for efficient panel processing and a rigid structure for a lifetimes service.

EN-EngineeringConstruction-Brochure-Advantica® for refrigerated trailers

Advantica® pre-finished steel for refrigerated trailers

EN-EngineeringConstruction-Datasheet-Advantica® L Control datasheet

Advantica® L Control datasheet

EN-EngineeringConstruction-Datasheet-Advantica® SDP 35 TR datasheet

Advantica® SDP 35 TR datasheet

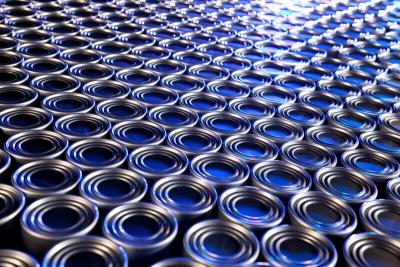

Our innovative range of steel products for use in refrigerated commercial vehicles have been developed to ensure the world’s leading trailer manufacturers get the best from our pre-finished steel solutions.

We have taken our knowledge and expertise from both the construction and manufactured goods sectors and re-engineered our Advantica® pre-finished steel to provide a ready to use, optimised solution for the inner and outer layers of composite panels used in the construction of refrigerated trailers.

Specifically developed to offer improved adhesion and create a superior bond, this ensures that the insulated panels are capable of coping with the most demanding environmental forces.

Our pre-finished steel provides the material of choice to help trailer manufacturers meet the challenges they face to provide clients with superior vehicles that offer benefits including:

- Light weighting

- Durability

- Thermal efficiency

- Accredited food safe compliance

- Ease of cleaning

- Aesthetic finish

- Sustainability

- Flexible and economical processing

Trailer manufacturers

Advantica supports production efficiency and legislation compliance by:

- Manufacturing efficiencies achieved through an automated steel production process.

- Ease of use and bonding capability.

- Ready to use solution that requires no overpainting

Trailer owners

Advantica supports reduced running costs, resulting in lower cost of trailer ownership:

- Provides excellent thermal efficiency and minimal permeability therefore reducing cooling costs.

- Abrasion and corrosion resistance on external face and robust internally to provide a longer-lasting and durable trailer panel solution.

- Robust and moisture tight, providing consistent performance even when damaged.

- Easy to clean internally and externally.

Advantica® L Control typical properties

(Internal roof and wall application)

| Property | Unit of measure | Result | Test standard |

|---|---|---|---|

| Nominal organic coating thickness | μm | 120 or (150 on request) |

EN 13523-1 |

| Specular gloss (60°) | GU | 8-15 | EN 13523-2 |

| Pencil hardness | >4H | EN 13523-4 | |

| Adhesion after indentation | T | Pass | EN 13523-6 |

| Adhesion on bending | T | 0 | EN 13523-7 |

| Flexibility (minimum bend radius) | T | 0 | EN 13523-7 |

| Scratch resistance | g | 4000 | EN 13523-12 |

| Corrosion resistance: Neutral salt spray | hours | 500 | EN 13523-8 |

| Corrosion resistance: Humidity | hours | 1500 | EN 13523-25 |

| Fire resistance | B-s1,d0 | EN 13501-1 | |

| VOC | A+ | EN ISO 16000-9:2006 | |

| Service temperature range | oC | -40 to +60 |

The figures contained in this table are properties and do not constitute a specification.

If forming pre-finished steel below 16oC please consult Tata Steel for further information.

Humidity performance subject to specification such as minimal metallic coating weight.

Foodsafety: compatible for continuous and direct contact with dry, aqueous and acidic foodstuffs.

Not suitable for outdoor use.

Advantica® PR TR (HA) typical properties

(Intermediate parts application)

For typical property information for Advantica® PR TR (HA) please contact Tata Steel.

Advantica® SDP 35 TR typical properties

(External roof and wall application)

| Property | Unit of measure |

Result | Test standard |

|---|---|---|---|

| Nominal organic coating thickness | 35 | EN 13523-1 | |

| Specular gloss (60o) | GU | 20-80 | EN 13523-2 |

| Adhesion on bending | T | 1 | EN 13523-7 |

| Flexibility (minimum bend radius) | T | 2.5 | EN 13523-7 |

| Pencil hardness | F-HB | EN 13523-4 | |

| Scratch resistance | 9 | >1800 | EN 13523-12 |

| Abrasion resistance (Taber, 250 rev. 1 kg, CS10 wheels) |

mg | <25 | EN 13523-16 |

| Corrosion resistance: Neutral salt spray | hours | 500 | EN 13523-8 |

| Corrosion resistance: Humidity resistance | hours | 1000 | EN 13523-26 |

| UV resistance category | Ruv3 | EN 10169 | |

| UV resistance (QUVA) | hours | 2000 | EN 13523-10 |

| Cyclic corrosion test (delamination on scratch): 6 cycles |

mm | <2 | VDA 233-102 / EN 11997 |

| Cyclic corrosion test (delamination on scratch): 12 cycles |

mm | <3 | VDA 233-102 / EN 11997 |

| Diesel test (change of appearance) | Visual | No | EN ISO 2812-T4 |

| Pancreatin test (change of appearance) | visual | No | EN ISO 2812-T4 |

| Stone chip resistance (2 x 500g, 2 bar) | Class | ≤1.5 | EN ISO 20567-1 VDA 621-427 |

| Steam jet test | Class | 2 | EN ISO 16925 |

The figures contained in this table are properties and do not constitute a specification.

If forming pre-finished steel below 16oC please consult Tata Steel for further information.

Advantica pre-finished steel for refrigerated trailers has been subjected to extensive testing and is well-proven in a wide variety of applications.

Our products which are fully REACH compliant and chrome free, have been designed to provide exceptional performance, meeting the highest industry standards as required by end-users.

Highly resistance to the daily pressures that will be placed upon the internal and external faces of the main trailer (transporting, loading and unloading), Advantica offers excellent levels of resistance to corrosion, damage, scratching, abrasion and wear and tear.

Robust in use

Internally, steel’s robustness makes it the ideal choice for providing a long-lasting composite panel solution that will cope excellently with the extensive day-to-day loading operations it will endure.

Externally, steel offers excellent abrasion and corrosion resistance and is capable of withstanding the wear and tear it can be subjected to including demanding weather conditions and road debris.

Moisture resistant

Advantica pre-finished steel composite panels have superior moisture ingress resistance, and even if damaged the integrity of the pane is uncompromised as the robust steel layer won’t allow moisture to enter the insulation and surrounding surface area.

Easy to clean

The risk of contamination from one cargo to another is always a concern but can be dealt with easily through a routine cleaning procedure that is simple and effective:

- High pressure water and mild detergent

- Thorough rinse with clean water.

Please contact Tata Steel for advice on chemical resistance.

Easy to repair

Advantica offers benefits for trailer maintenance and repair. A pre-finished steel composite panel system gives trained professionals the option to repair damage with cost-effective sectional repair, or full panel replacement.

Externally pre-finished steel composite panels can be overpainted and decals applied to give a new lease of life.

Food safe certification

Independently tested and certified for volatile organic compounds (VOC) and fully complaint with EN 16000-9. Advantica L Control achieved an A+ rating.

Subjected to rigorous industrial testing Advantica L Control meets stringent requirements for continuous food contact. Tested by an independent accredited laboratory to EN 1186, EN 13130 and CEN/TS 14234 standards.

EN-Engineering-Contact-Advantica Maubege

Advantica® pre-finished steel

Tata Steel

Maubeuge

22, avenue Jean de Beco

BP 12099 Louvroil

59606 Maubeuge Cedex

France