HMS Queen Elizabeth

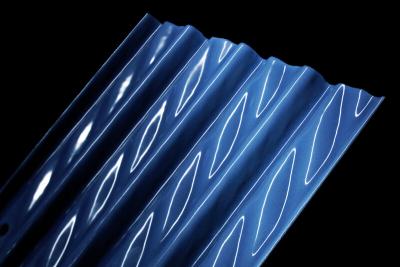

Transport case study, HFI conveyance pipe

The challenge

The Queen Elizabeth class of aircraft carriers are the largest and most powerful warships in the Royal Navy. They need to be both agile and incredibly fuel efficient while carrying a load of up to 24 F-35B Lightning II aircraft, plus additional helicopter support if required.

Designed with twin islands which keep the running of the ship separate from the flying operations, each Queen Elizabeth carrier represents eight acres of sovereign territory which is versatile enough for operations which range from supporting combat to humanitarian aid and disaster relief.

The solution

Tata Steel worked with customer BAE Systems for over 12 years on this project from design through to delivery.

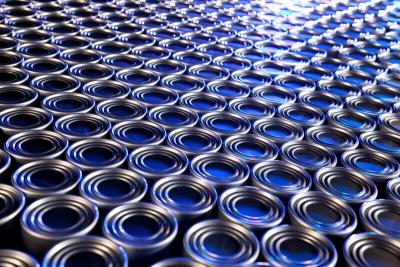

Tata Steel supplied 40,000 tonnes of steel - over 90% of the steel used in the build - including conveyance pipes from Hartlepool and feedstock from Port Talbot strip mill. Tata Steel metallurgists developed two new steel grades, FH36 and EH46: lighter, stronger steel created specifically for the future flagship of the Royal Navy. Both the new grades achieved Lloyds Registry approval.

Phil Knowles, Commercial Manager at Tata Steel, said: “It has been fascinating to be part of such an exciting and high-profile project. HMS Queen Elizabeth is the largest warship ever built for the Royal Navy.”

EN-Construction-Contact-Tubes-Technical

Structural Hollow Sections Technical Team

Tata Steel

Weldon Road

Corby

Northants

NN17 5UE