Ossi Varjoranta has been the production manager in Naantali since November last year. Originating from Jämsä central Finland, Ossi's career started perhaps logically at the UPM Jämsänkoski paper mill. A production technology engineer who used to work in paper factories Turku became familiar during his bachelor studies. So Ossi decided to pack his bags and move permanently to Turku. The employer became Bayer, the giant of the pharmaceutical industry. In his previous activities, Ossi has gained solid experience in both production, maintenance, and supervisory positions.

Well Ossi, how has it been? "The first months have been great, and I've been received really well to the job. We have very professional and committed personnel and I learn from each of them every day," says Ossi. "Safety is a clear priority number one here. It's not something we choose to bend even a bit. You quickly notice that it's a way of thinking that has caught on with everyone, and work is constantly being done to improve safety. More than 2,000 accident-free working days do not come with just words, but with hard work," sums up Ossi.

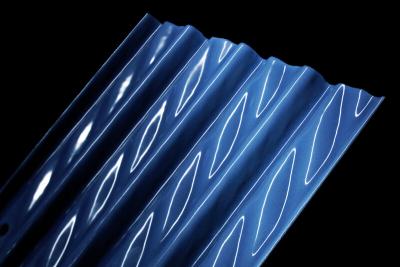

Can handling steel in any way be compared to your previous jobs? A finger goes to his temple as Ossi scratches his head for a moment and then states: "There are fewer regulations than, for example, in the pharmaceutical industry, which does allow a certain amount of freedom in the job. The freedom to do accelerates development and enables more agile deliveries to customers. Similarities can also be found, for example, in relation to the traceability of materials, which is top notch in both."

"It's great to learn more and more about the steel business. We have excellent communication between the customers and production. We have large storage facilities and the guys have kept the hall tide up and things in order. Investments has also been made, e.g. during the spring for a new plate bundle lifter which helps us to use the space even more efficiently," says Ossi. Did anything surprise you when you came to the new job? "Yes, the big surprise was that when you order from us you can actually get the goods the next day. I didn't realize that when I arrived here to work. It's strange that you order home dust bags from an online store, and it takes a week, but ordering 30 tons of steel and you'll get it tomorrow," Ossi laughs.

As the conversation turns to climate change and carbon neutrality, Ossi has a clear opinion. "That is a matter that is on the table, as it should be. Tata Steel has been working on lowering emissions for decades, and as a reward from this work Ijmuiden steel mill is ranked third among the cleanest steel mills in the world. In addition, Tata Steel has also come up with a great road map to produce carbon-neutral steel. Maybe even the best in the whole industry. In Naantali SSC, we were also able to contribute and set an example for our other by becoming first carbon-neutral Tata Steel site. After that, others have also moved ahead with their projects and slowly the entire production chain is changing. It's great to be inside the company as an example to other Tata people and to give advice on how to achieve this ambitious goal.”

That’s exactly how it is. Welcome to the company, Ossi.

EN-Service centres-Contact-Finland Naantali

Finland - Naantali Steel Service Centre Oy

Naantali Steel Service Centre Oy

Rautakatu 5

21110 Naantali

Finland