EN-Construction-Product-Fast-Fit-Overview-SDP65

Created to help tackle the skills and supply chain shortages within construction, Trimawall® Fast Fit is a DfMA (Designed for Manufacture and Assembly) solution that can help unlock additional capacity both off-site and on-site, facilitating on-time, on-budget delivery of projects.

The Trimawall® universal mounting and panel system can be used throughout a building, both as a façade and internal fit out as a hybrid solution mounted over a wide range of structural wall types.

The internal wall fit out system provides a strong and versatile alternative to traditional building materials. With interior panels supplied with a choice of Colorcoat® pre-painted finishes, Trimawall® requires no wet trades to complete and avoids on-site plastering dust.

In combination with modular wiring solutions, the demountable panels and accessible services cavity simplifies and speeds up the complete M&E installation making it a great choice for large building projects such as schools, hospitals, offices and housing schemes, where quick build times and guaranteed quality are of particular importance.

EN-Construction-Product-Fast-Fit-With-Colorcoat-SDP65

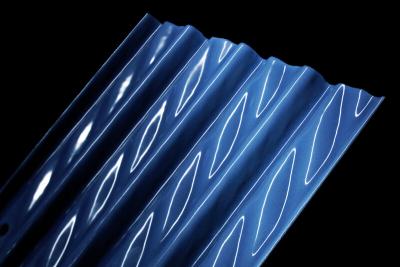

Colorcoat® SDP65 utilises cutting edge three layer manufacturing technology to create an optimised, robust, chrome free pre-finished steel product.

With a greatly enhanced range of colours and effects, that includes the Elements selection of natural metal colours, enhanced metallic sparkle effects, as well as a wide selection of inspired Matt shades such as Matt Metallics ideal for feature walls.

| Front skin | 0.50mm Colorcoat SDP65 |

| Core | 9mm Plywood |

| Back skin | 0.50mm Colorcoat® |

| Panel Weight | 13.9 kg/m2 |

| Maximum width | 1200mm |

| Maximum length | 3000mm |

| Specular gloss (60°) | GU | 25 - 35% | EN 13523-2 |

| Pencil hardness | H | EN 13523-4 | |

| Scratch resistance | g | 3000 | EN 13523-12 |

| Corrosion resistance: | hours | 1000 | EN 13523-8 |

| Neutral salt spray | |||

| Corrosion resistance: | hours | 5000 | EN 13523-25 |

| Humidity | |||

| Internal Environment Classification | CPI5 | EN 10169-2022 | |

| Service temperature range | oC | -40 to +60 |

EN-Construction-Product-Fast-Fit-Benefits

Future proofing buildings

The versatility of Trimawall® Fast Fit’s individually demountable panels and accessible service cavity means that it can be installed, demounted and then reconfigured to adapt to changing needs of the building users.

Trimawall® Fast Fit delivers benefit for both construction companies and end clients

For Healthcare: Building Systems UK has partnered with Construction Specialities to create a range of Acrovyn skinned panels to create hygienic, healthcare approved walls in a wide range of colours.

For Schools: The durable magnetic Colocoat® walling is perfect for classroom displays, maintaining its appearance term after term, avoiding the expense and disruption of regular repainting.

For Commercial Offices and Retail: The individually demountable panels allow spaces to be adapted to changing occupier requirements, with panels relocated, reconfigured or replaced, enabling building & brand refreshes to be conducted overnight.

For Volumetric builders: With a systemised set of pre-cut, pre finished panels, off-site value can be maximised while factory productivity & output is increased.

For Traditional construction: Having a single pre-finished panel, rated to severe duty deflection & patressesing standards helps to minimise deliveries to site, on site waste and the need for wet trade finishing, vastly simplifying crew logistics and condensing build schedules

For M&E Installers: The pre-cut panels and accessible service cavity eliminates the hassle of threading and wall rework, reducing on site errors, ensuring detail consistency, and facilitating a much faster, simpler M&E install.

EN-Construction-Product-Fast-Fit-Sustainability

Trimawall® Fast Fit is manufactured and delivered as a kit of parts in order to minimise the environmental impact during construction and fit out.

A designed kit of parts avoids over ordering, minimises deliveries, on-site cutting waste, and snagging.

One robust prefinished panel, reduces breakages / water damage during installation and minimises the use of sealants, glues, paints, further reducing waste disposal.

The 11mm thick Trimawall® panel incorporates a hygienic pre-finished front skin as part of a robust steel composite that provides all the requisite pattress strength required for Severe Duty rated walls.

Being delivered to site already cut to size with the Fast Fit clips pre-installed, Trimawall typically requires 70% less material deliveries and all but eliminates the on-site waste commonly associated with cutting, plastering & finishing internal walls.

Steel: an infinitely recyclable building material

With an extended first use design life and zero degradation in materials properties when recycled, steel is unlike nearly all of the other construction materials, offering sustainability benefits throughout in-use and end of life phases of a building’s life. Tata Steel UK’s manufacturing processes are carefully controlled to the highest environmental quality standards and are ISO 14001 certified with the widest portfolio of construction products certified in the world.

EN-Construction-Product-Fast-Fit-Kit of parts

Quick and easy installation

Four standard components provide a universal mounting solution:

| Part | Description | Material | Dimensions | Standard Lengths | Weight (kg/ln) | |

| 1 | Horizontal Mounting Rail | Lipped C section provides main mechanical fix into structural wall | 1.6mm Galvanised steel | 55mm x 20mm | 3000mm | 1.5 |

| 2 | Base Angle | Z profile create a level base for panels and support for skirting | 2.0mm Galvanised Steel | 65mm x 60mm x 65mm | 3000mm | 3 |

| 3 | Sliding Connector | Twist in fit steel connetor allows easy positioniong of vertical rails | 1.0mm eCoated spring steel | 62mm x 32mm | n/a | n/a |

| 4 | Vertical Retaining Rail | Push fitted onto sliding connectors it then provides the receptor for Trimawall panels | 1.0 mm Galvanised steel | 53mm x 34mm | 2800mm | 1.7 |

EN-Construction-Product-Fast-Fit-Tool-Free

Fast & efficient wall finishing

The steel skinned composite panels are mounted using Trimawall® Fast Fit’s patented clip system that is pre-applied to the vertical edges of the composite sheet in our factory.

On-site, the panels can typically be lifted with vacuum lifters and push fitted by a 2 person installation crew. With the pre-finished panel requiring no additional wet trade finishing Trimawall® Fast Fit helps simplify and condense the total fit out and finishing process.

Individually demountable panels

Trimawall® Fast Fit’s panels can be individually demounted by a 2 person crew using vacuum lifters and the Trimawall demounting tool. The panels can be demounted & reinstalled multiple times without compromising performance or aesthetics. Not only does this allow for easy access to the M&E services within the cavity for maintenance or upgrading, but it allows panels to be relocated, reused, replaced to help reconfigure and enhance buildings over time.

EN-Construction-Trimawall®-fast-fit-internal-wall-installation-videos - temporary version

Trimawall® Fast Fit flat wall installation guide

Click here to watch

Trimawall® Fast Fit internal corner installation guide

Click here to watch

Trimawall® Fast Fit demountable tool guide

Click here to watch

EN-Construction-sustainability-optemis-carbon-lite

The launch of Optemis Carbon Lite is an important step in our ongoing decarbonisation journey. It demonstrates our progress and represents a unique solution for customers in the form of a flexible, lower CO2 steel offering.

Optemis Carbon Lite is a fully certified in-setting scheme with CO2 savings achieved from implemented projects, verified by a 3rd party auditor, DNV, and credited to our CO2 bank. Our continued commitment to decarbonisation means reductions in CO2 emissions can now be passed on to our customers, enabling them to achieve immediate Scope 3 emission savings.

Revenues generated from the sale of Optemis Carbon Lite declarations are used to fund additional decarbonisation projects, generating further CO2 savings to be verified by DNV and speeding up our decarbonisation efforts.

By buying Optemis Carbon Lite from Tata Steel UK we, and our customers, will be actively contributing to a reduction in atmospheric CO2.

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-Product-Fast-Fit-downloads

Find related downloads below for your project specification: